- info@activeenergyadvisers.co.uk

- 07787438860

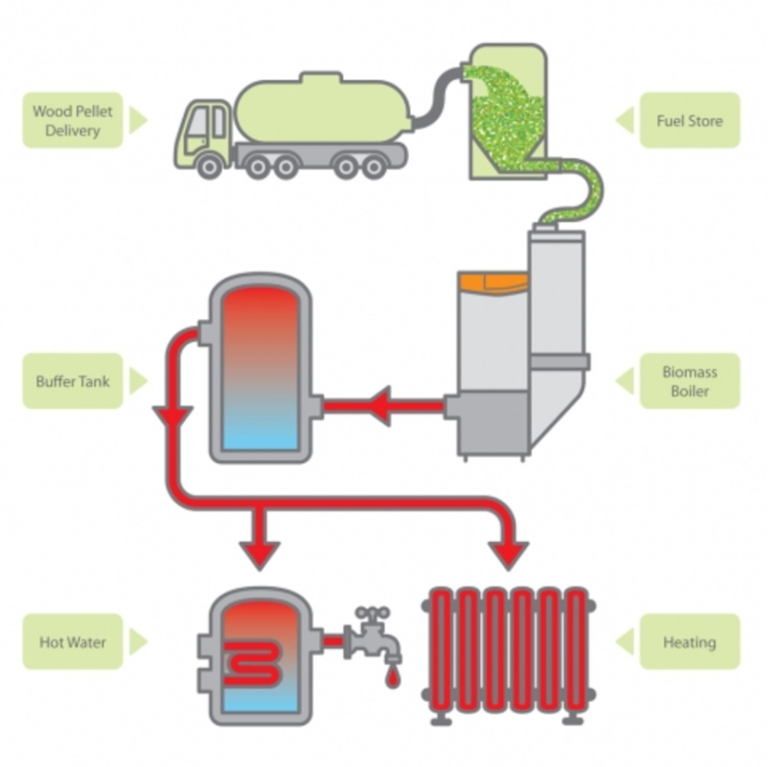

A biomass boiler works in a very similar way to conventional boilers, combusting fuel to produce heat that is then used to heat water. Biomass boilers are normally substantially bigger than their fossil fuel-burning brothers though, for a number of reasons. Firstly, since they are burning wood pellets or chip, as opposed to gas, the boiler needs to be larger to hold the larger volume of fuel.

In addition, you may wish to install an automatic feed hopper on your biomass boiler, which will require additional room. This hopper stores a large volume of the wood pellets or chip that is then automatically fed into the boiler as required, meaning that the boiler needs to be refuelled very infrequently.

It is also a good idea to have a store of the wood pellets or chip, at your property so you can keep producing heat if for some reason there is an issue with your fuel supplier. Ideally this should be close to where the fuel is delivered to your home/business, to minimise the distance you have to move it.

Most residential biomass boilers can also run on logs as well as the wood/pellets chips, so if these are in plentiful supply or if you can source them cheaply or even for free, it will dramatically reduce the operational running cost of your biomass boiler.

Every four weeks or so, the biomass boiler will need to be emptied of the ash. This can be put straight onto a compost heap to help fertilise the soil.

Biomass boilers are designed to work all year round; however, you may choose to turn them off in the summer. They can be coupled with solar thermal heating, providing you with your hot water, during the warmer summer months.

The combustion of virgin timber and clean biomass fuel is regarded as solid fuel combustion and is regulated accordingly under the environmental Permitting Regulations or the Clean Air Act 1993, depending upon the thermal input of the appliance.

However, where virgin timber is mixed with waste timber, or any other waste, the mixed load is classed as waste wood (see Biomass WID/EID Boilers for more information on waste wood).

Biomass boilers measure up very favourably in terms of running costs vs. natural gas, heating oil and especially electricity. The numbers can all be seen in the table below.

Figures courtesy of Biomass Energy Centre

Fuel Type | Price per Unit | kWh per unit | Pence per kWh |

Wood Chips | £100 / tonne | 3,500kWh / tonne | 2.9p / kWh |

Wood Pellets | £200 / tonne | 4,800kWh / tonne | 4.2p / kWh |

Natural Gas | 0.3p / kWh | 1 | 0.3p / kWh |

LPG | 0.5p/ kWh | 1 | 0.5p/ kWh |

Heating Oil | 60p / litre | 10kWh / litre | 6.0p / kWh |

Electricity | 14.5p / kWh | 1 | 14.5p / kWh |

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.