- info@activeenergyadvisers.co.uk

- 07787438860

A Biomass WID/IED boiler works in the same way as a standard biomass boiler but has some very key differences. One being the fuel its burning and two being the equipment extras you will need to do able to cover regulations.

It is also very important to source a boiler that has been installed in the UK under the regulations that you need to comply to. This is because many companies claim to comply with this, however, there are many regulations that the boiler manufacturers need to comply with. For example under the WID / IED regulations the boiler must have a combustion chamber that holds the gasses inside the boiler for a minimum of 2 seconds, it must also have a fossil fuel burner to pre-heat the combustion chamber as the regulations state that the waste cannot enter the boiler until the chamber has reached 8500c, it must also do this in reverse when the waste is stopped being fed into the boiler.

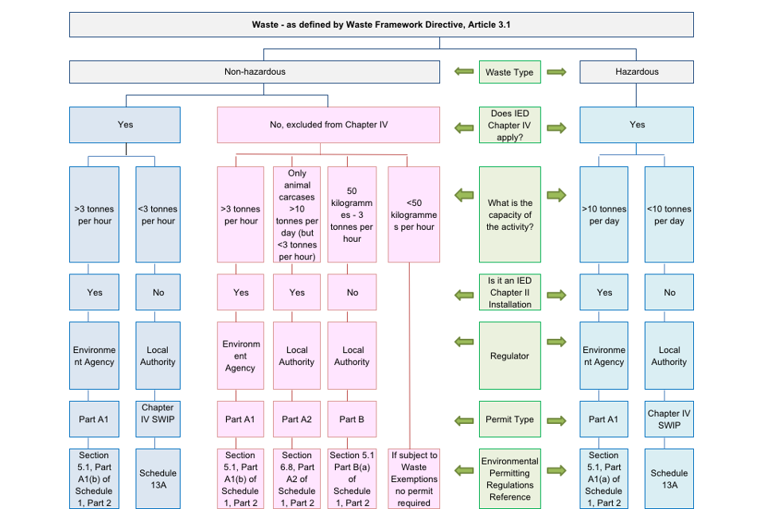

Once the fuel has been categorised the boiler and equipment can be specified for the requirements needed for any given site.

Below is a list of items that can form part of a biomass system. These items can vary by a huge amount depending on the type of boiler required, for example a standard boiler burning “A” grade wood waste would not require any flue monitoring equipment, whereas a boiler under a part B permit may require £30,000 pounds worth of monitoring equipment and a boiler that is WID/IED compliant may require £130,000 Pounds worth of constant flue monitoring equipment. It is therefore very important to correctly define your waste!!!

Controls interface

Non virgin timber such as off cuts, shavings, chippings and sawdust from the processing of non-virgin timbers (whether untreated or treated) are waste wood. Untreated non-virgin waste wood, despite not having been treated with any chemicals, is waste wood. Treated

non-virgin timber is any timber that has been treated (e.g. to enhance the performance of the original wood) or made into panel board of any sort is waste wood.

Any biomass material that is ‘waste’ would be subject to the Industrial Emissions Directive (IED) regulations as applied to the waste incineration process. However, the IED provides for exemption of certain biomass materials and these are not subject to the operational requirements of the IED and, dependant on the net rated thermal output of the installation, can be regulated by the Local Authority.

“Clean” recycled wood – Material produced from packaging waste and secondary manufacture including untreated process off-cuts, scrap pallets, packing cases and cable drums. (that have not entered the waste stream, usually produced and used on the same site)

Industrial feedstock grade – May contain Grade A wood together with other waste wood from construction and demolition activities, transfer stations and solid wood furniture manufacture.

Includes Grade A & B wood plus material coated and treated with preservatives typically including a high content of panel products. Suitable only for IED Chapter IV Compliant Boilers.

Hazardous waste – This includes all grades of wood including treated material such as fencing and trackwork and requires disposal at special hazardous facilities.

Active Energy Advisers have been in the waste to energy market for the last 10 years and have many installations that conform to differing standards for the Environment Agency

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.