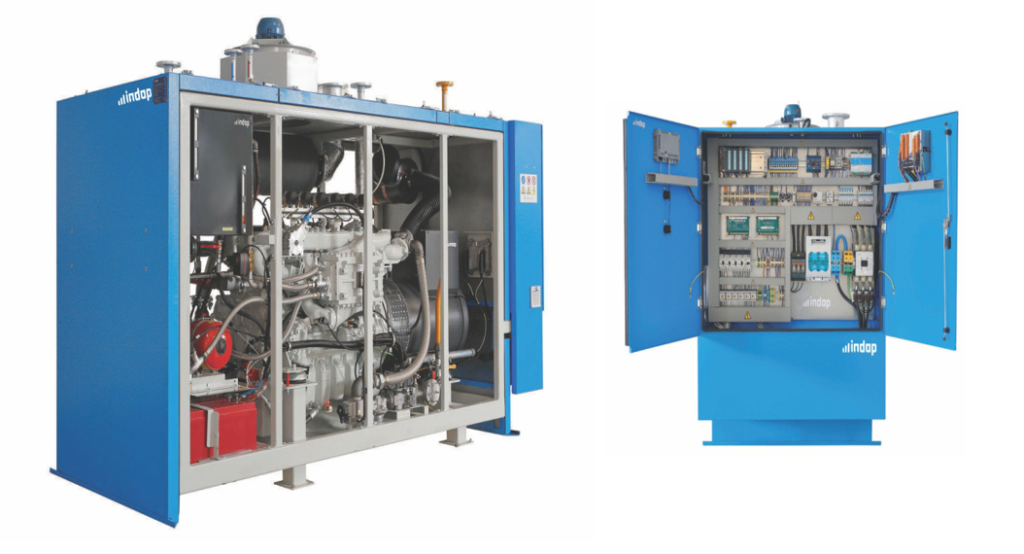

Unit: 1.2 MW CHP

Capital Cost: £970,000.00

Simple payback: 1.8 years

Order to commission: 5 months

CO2 Savings per annum: 276,840 kgs Approximate until unit has been running 1 full year.

Type of Fuel: Mains Gas

Service Intervals: Every 1800 hours

Automatic Modulation: 50-100%

The Finance Director from Thumbs Up, a large plastics mouldings company in Bury, came to us via a recommendation. Their decision to use CHP was focused on the significant savings they would make on their energy costs.

Originally, they came to us looking to reduce their electricity consumption, with no need for the hot water the CHP would produce. Upon carrying out a full site survey, we found an existing chilled water system, which we decided to utilise by running the hot water created by the CHP through it. By providing and installing an absorption chiller, the heat will be turned into chilled water, which will then be fed into the existing, process chilled water system.

Due to the size of the premises and the 24 hour, 7 days a week demand from the machinery, we decided the 1.2MW CHP best suited the application, along with the client’s budget and current work commitments firmly in mind. This unit will produce approximately 75% of their electrical requirements, contributing approximately 200KW of chilled water to their chiller system.

‘We take a great amount of pride in being able to offer a bespoke and personalised service that continues from the first enquiry, right through to completion and beyond. We’re always willing to go that extra mile to ensure our customers receive the level of customer service that will keep them coming back to us’.